Back to Blog

Dormant Reliability—How to Account for it in Reliability Predictions

By Daniel Foley

A component or system is considered dormant when it does not have any operating conditions applied to it. Most of a system’s dormant life will take place in a PHS&T (Packaging, Handling, Storage, and Transportation) environment. When designing a system, it is important to understand what is going on around and within the system during operating and dormant periods. To understand Dormant Reliability, we need to understand the factors involved in causing something to fail.

The two biggest factors that affect the reliability of components/parts are the environment and the stress on the parts. The environment is the conditions surrounding the system during its life, such as temperature, humidity, and vibration. This may be specified for use in a reliability prediction as a worst case scenario or in a set of life cycle phases. The stress is the conditions within the system during its life, such as power applied, torque applied, pressure, thermal expansion/contraction, and other forces. This again may be specified for use in a reliability prediction as worst case scenario or in a set of life cycle phases.

The maximum and minimum allowable environmental conditions should be calculated and coordinated with the end user to ensure the system is stored properly, in addressing dormancy. Improper temperature storage can be especially evident in plastic and rubber based items, as rubbers can harden and plastics can melt. Whereas, improper humidity storage will show itself in metals where corrosion can take its toll. Transportation conditions, such as vibrations, can cause items to loosen, increase the point load stresses, and increase material fatigue. Understanding and controlling these variables will help improve the availability of the system when called upon.

Second to the dormant environment, dormant stresses will have an effect on the system’s reliability. Most static mechanical items will not experience a significant difference between its operating stresses and its dormant stresses. This is because the static forces / energy acting on static mechanical items such as fasteners, housings, covers, brackets and others will be very similar when operating or dormant. Operationally, active mechanical parts and electronic components can see differences in their dormant and operational stresses. For example, a car rim when removed from the axle will not have the stress of the car’s weight unlike if it was stored while attached to the car. Electronic components when dormant will not experience any electronic energy.

Reliability predictions are generally done considering either a worst case scenario or life cycle phases. The worst case scenario is when we limit analysis to the worst possible conditions that the system will endure during its life as variables for the prediction. This is a conservative approach as it will give you lower reliability than what will be seen in the field. A more accurate approach is to use life cycle phases. Life cycle phases try to define the most accurate variables the system will experience during its lifetime and to define the amount of time it will see those conditions. Although this maybe harder to define than the worst case scenario, it will lead to an analysis result more in line with what will be seen in the field. Dormancy should be one of the life cycles phases used under this approach.

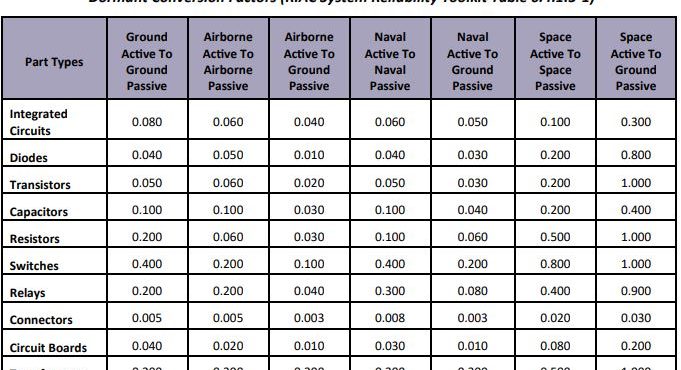

Reliability Information Analysis Center (RIAC) developed a method to predict the reliability of dormant electrical components using failure rates from an active system. They estimate the dormant reliability by applying conversion factors to parts count failure rates (this is documented in section 6.4.1.5 of the RIAC System Reliability Toolkit). Each conversion factor is specific to different types of electronic parts for each of the seven scenarios. These factors can be found in the table below.

Many members of ALE’s team have experience in performing dormant reliability predictions and factoring the results into the life cycle analysis. We would be happy to answer any question you have regarding this subject.