Back to Blog

The Case for Early Obsolescence Management

Obsolescence is the process of becoming obsolete or the condition of being nearly obsolete[1]. Obsolescence Management (OM), therefore, is the management of the process of becoming obsolete. The definition reiterates the fact that all things become outdated, eventually.

Diminishing Manufacturing Sources and Material Shortages (DMSMS) is defined as “The loss or impending loss of manufacturers of items or suppliers of items or raw materials [that] may cause material shortages that endanger a weapon system’s or equipment’s development, production, or post-production support capability”[2].

Obsolescence Management and DMSMS are slightly different but wholly connected – the management of items becoming obsolete and the management of manufacturers and suppliers, respectively. What does this mean for your Program? Let’s examine a favorite “typical system” used during training sessions at ALE. The bicycle.

At the top level, the bicycle is composed of wheels, saddle, frame, handlebars, brakes, tire valves, pedals, and a chain assembly. Possibly there are some options, such as a reflector, basket, bell, and custom paint. Of course, we want a fast ride, so this bike uses a very light, composite-carbon frame. We also would like to take this off-trail, so opted for a digital compass and the exclusive Reggegio Mountain Trail “Never-Fail” 844 mm wheel and rim collection. The Reggegio wheels are slightly larger than standard ISO model, but the Vendor promises they are “Never-Fail”.

As our slightly customized bike is rolled off the production line, obsolescence does not feel like a concern. The frame is supplied to us by a long-time supplier known for quality, and the custom paint is MIL-C-46168 compliant. However, consider what would happen if shortly after our purchase of Reggegio “Never-Fail” wheels, the company is purchased by their rival, Parmigegio, and the wheels are promptly discontinued due to numerous lawsuits. NASA also announces a new technology that displaces the current magneto-inductive technology to counteract magnetic distortion with 100% accuracy.

Suddenly, the new bicycle design has an outdated sensor in the compass, and wheels that will no longer be available once our current stock is depleted. Concurrent with the loss of the wheels, our spare spokes, rims, tires, and reflectors may also be a concern. Replacing a set of wheels seems straight-forward, however the frame and chain assembly were customized to accommodate the larger wheel circumference. This cascading problem illustrates the potential for even new designs to quickly fall victim to severe, and costly, redesign activities.

Developing a process to manage potential obsolescence of the new design during the concept phase may have provided pause in considering a larger wheel size. The gold-standard in DMSMS Management Programs is SD-22, Diminishing Manufacturing Sources and Material Shortages (DMSMS)[3]. SD-22 provides an excellent basis for building a foundational DMSMS program. As our definitions illustrated, the program should aim to monitor both components that will become obsolete, and the suppliers and manufacturers associated with those components. As end items become more complex, additional layers of potential obsolescence become evident. Does the program rely on special tools for repair or manufacturing? Consider the software and firmware required to operate and diagnose the system. Does a new version of an assembly software impact related systems (think about what happens on a home computer when Adobe Flash or Java is updated)?

Certainly, a design team cannot predict future events or even be knowledgeable about every technology and supplier situation. To realize the best cost-avoidance objectives, SD-22 advocates for a proactive approach. How does a program with thousands or tens-of-thousands of components manage such massive amounts of data and “what-ifs”? Predictive software does a good job, but typically only considers the electronic world at the lowest level.

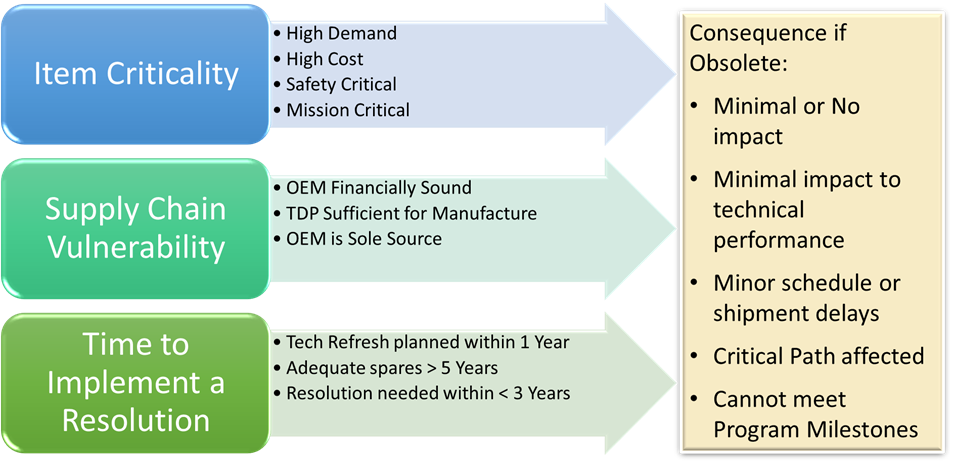

The most useful tool becomes then a Risk Priority Matrix (Figure 1).

This matrix provides the Program with ground rules for determining which obsolescence issues demand the most attention and resources. The Program Stakeholders will need to decide the factors that present the greatest risk to Availability and assign priority based on the most urgent issues. A rating system can be simplified to “low”, “medium”, and “high”, or it can be a slightly more complex formula with weighted scores. Rating systems may look at Item Criticality, Supply Chain Vulnerability, and the Time Required to Implement a Resolution.

Waiting for a component to become obsolete before acting invites the cascading effect to overtake a Program budget, or worse, cause safety and mission critical availability problems. However, the good news is remembering that OM is just the management of the process. Program equipment and components will all, eventually, become obsolete. Having an OM program does not mean replacing every component immediately. Managing the process provides the opportunity to plan for technical refreshes at appropriate times, make smart purchasing decisions, and positively impact Program Life Cycle Operation and Maintenance (O&M) costs.

It is never too early for planning. Even fielded systems can add an obsolescence component to the Engineering Change Proposal (ECP) process. I.e., Does this change impact Next Higher Assemblies with obsolescence issues? Is this a good time to re-look at the subsystem as a whole? Talk to suppliers and manufacturers during the ECP process for related components and support equipment requirements. Including Obsolescence issues with other Life Cycle Engineering activities during any phase of a Program will ensure the system is healthy (and available) from the initial production stages and beyond.

Article Authored by Karen Wisne

[1] Merriam-Webster.com. 2021. https://www.merriam-webster.com (21 April 2021)

[2] DoD 4140.1-R, DoD Supply Chain Materiel Management Regulation (23 May 2003)

[3] Defense Standardization Program Office (January 2016)